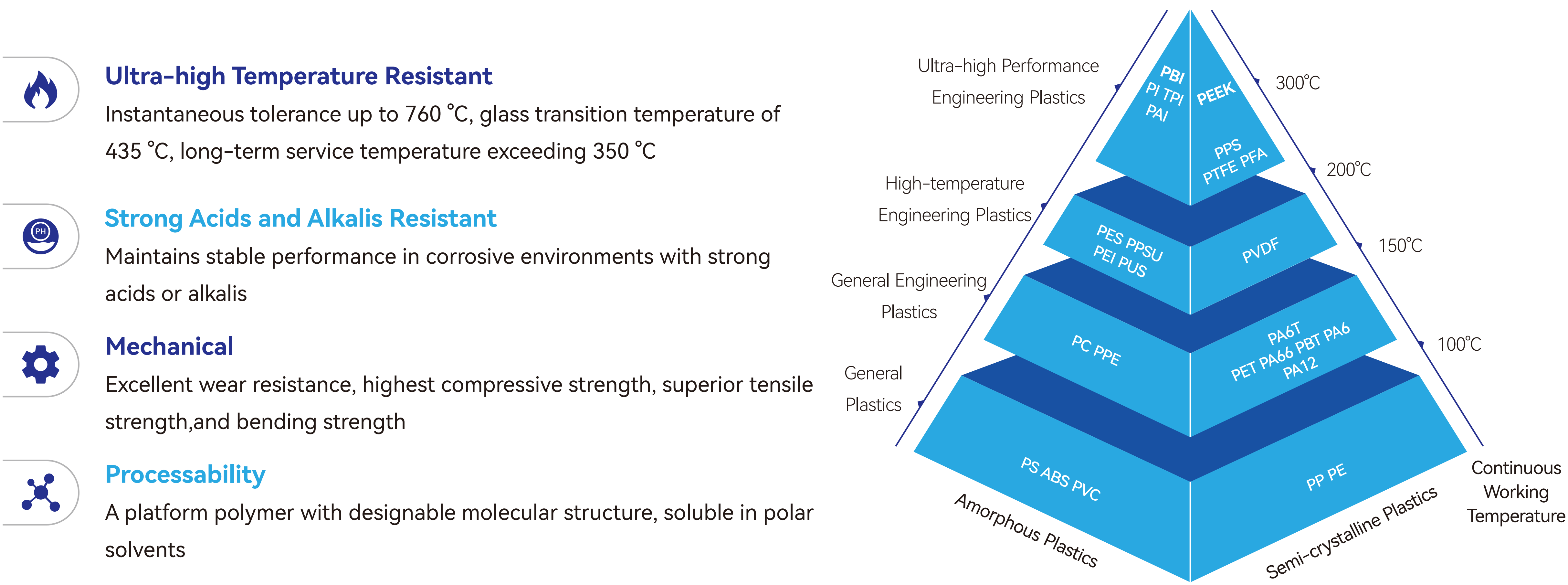

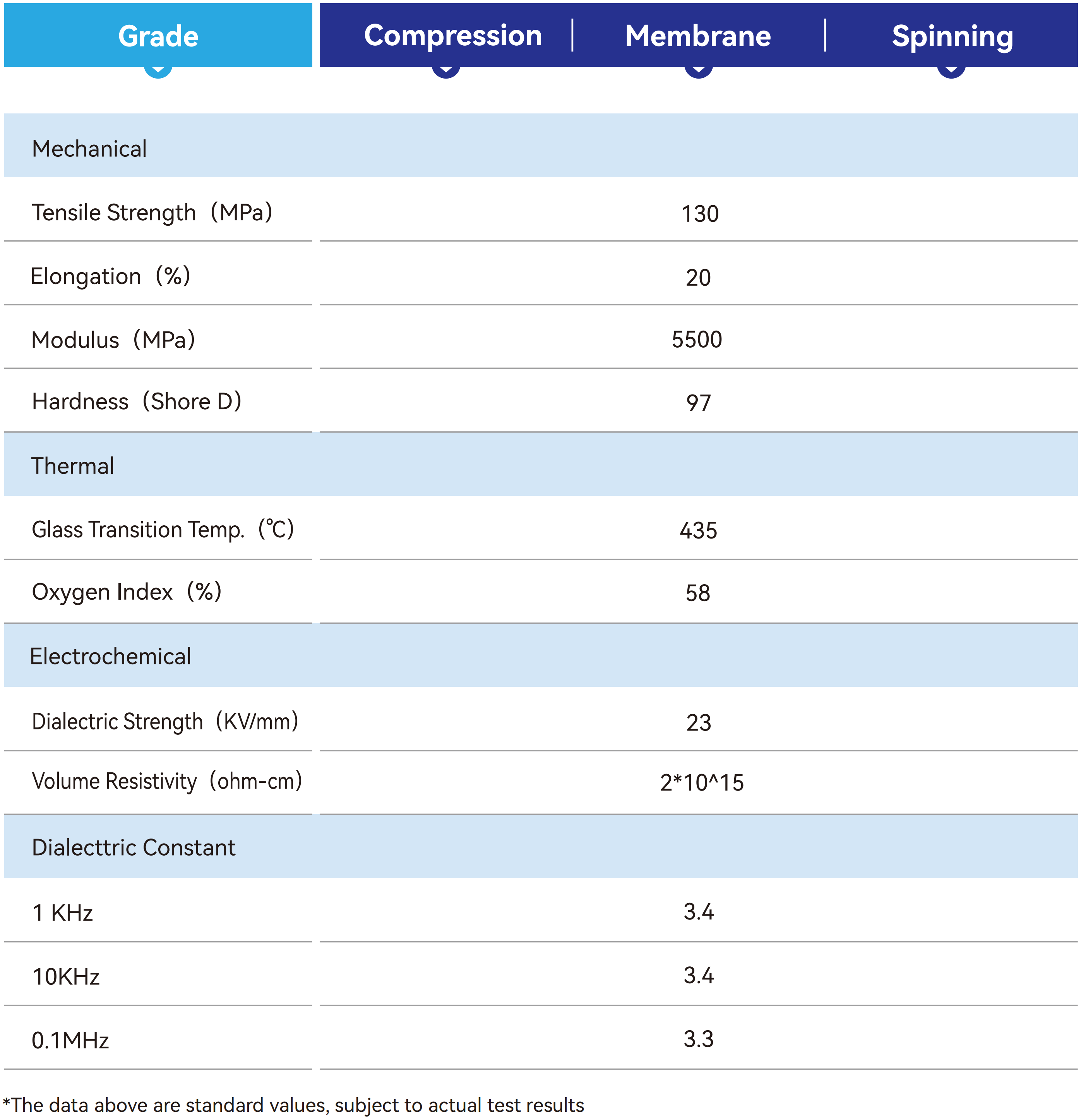

Repazole® PBI Resin demonstrates irreplaceable advantages across numerous industrial sectors due to its exceptional comprehensive properties. With a glass transition temperature of up to 435°C, it performs reliably in extreme high-temperature environments where other specialty engineering plastics fail. Its non-melting and non-flammable characteristics enable brief exposure tolerance to ultra-high temperatures of 760°C. Additionally, PBI exhibits outstanding resistance to strong acids and alkalis, superior mechanical strength, and excellent electrical insulation, establishing it as one of today's most elite specialty engineering plastics.

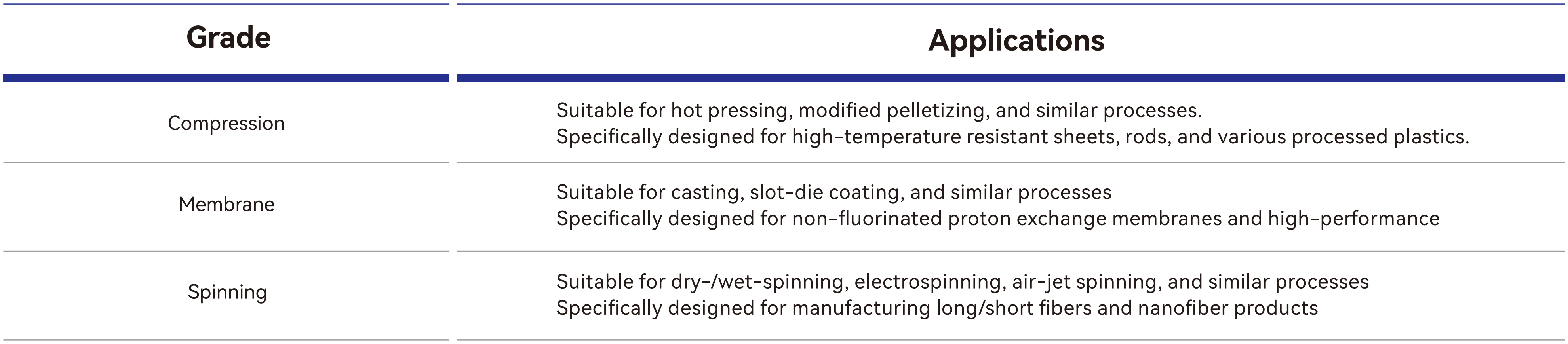

Riebom not only supplies Repazole® PBI in powder, but also dissolves it into dispersions of varying solid content and viscosity using polar solvents – tailored to specific application requirements – to cater to diverse processing needs

Follow Us